Our quality control system is fully implemented in accordance with the requirements and guidelines of ISO 9001, which ensures that our quality management, processes and product control meet the most strict requirements.

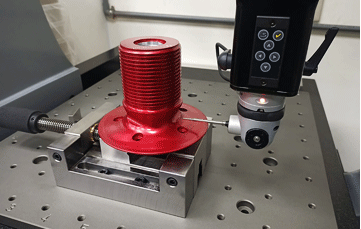

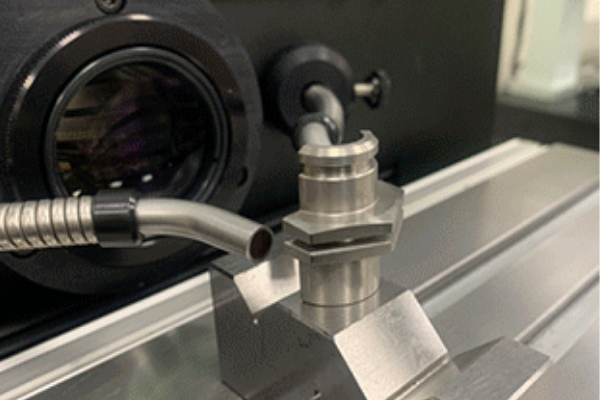

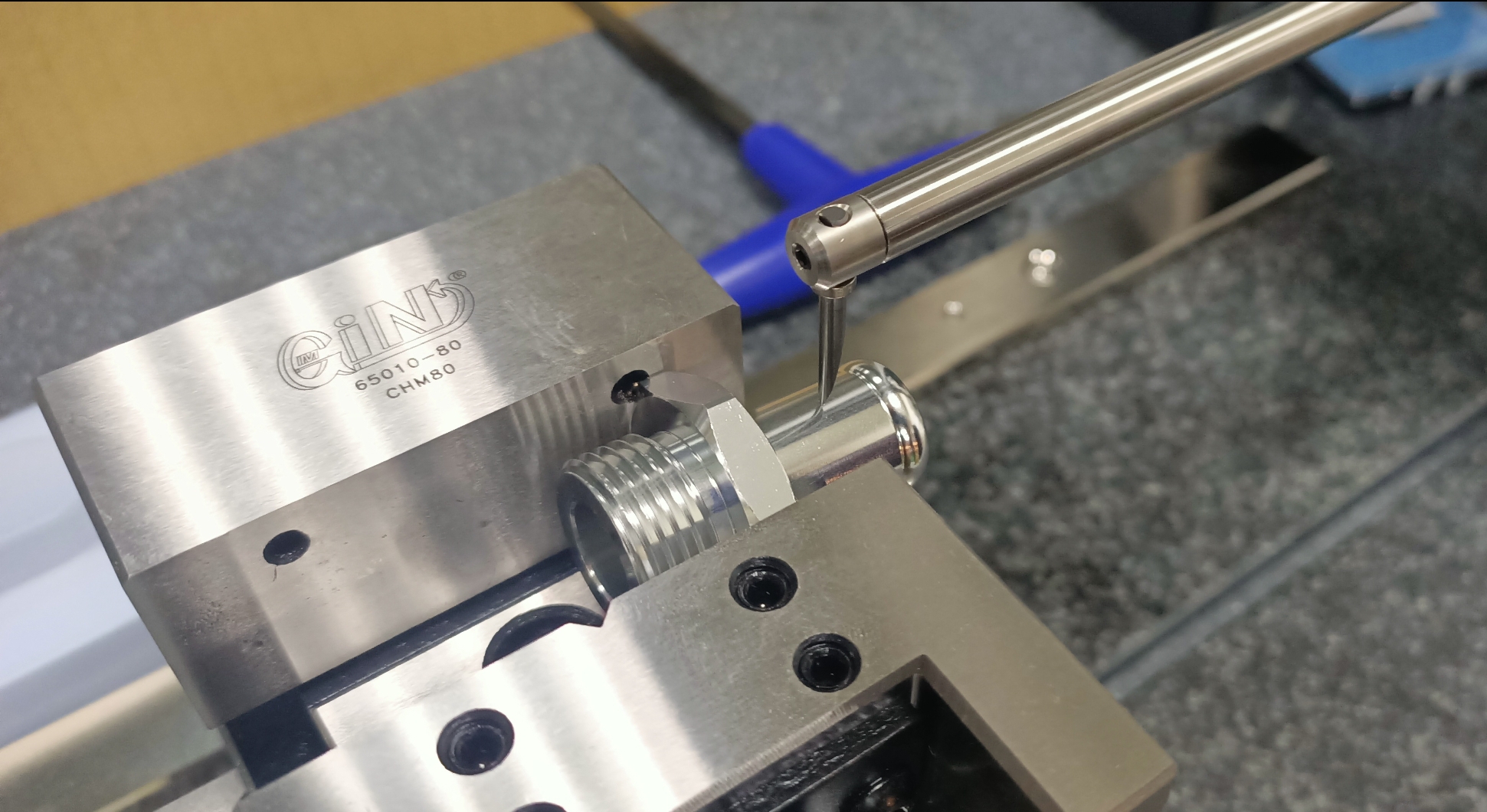

In order to ensure the quality assurance of our customers' products, our QC lab is equipped with advanced inspection instruments and measurement tools, including 3D coordinate measuring instrument, 2.5D image measuring instrument, optical projector and surface roughness meter...etc. We conduct strict standard inspection on the appearance, dimensional accuracy, roughness, hardness, etc. to ensure the consistent and stable quality of Fong Shen's precision parts.

Surface Treatment Inspection

For various surface treatment parts, rigorously carry out X-ray film thickness inspection of the part coating, fog test, layer color appearance inspection, etc. to meet or exceed customer requirements