In the 21st century, the global industrial division of labor has entered the era of OEM / ODM. In the whole development and supply chain, Fong Shen has over 20-years manufacturing and cooperative experience in the field of precision metal parts. We help our customers to maximize their R&D and design engineering functions, thus greatly increasing the added value of their products and creating a win-win situation.

Precision Parts

OEM / ODM Professional Manufacturer

Precision Parts

OEM / ODM Professional Manufacturer

Precision Parts

OEM / ODM Professional Manufacturer

CNC Capabilities

Collaborative Design Capabilities

Based on years of experience in OEM manufacturing and the accumulation of technical capabilities, our company can fully collaborate with customers in the development and design of new products at the early stage of concept development, from "conceptual communication → drawing of finished products → customer's signature → mold / fixture design → sampling → sample customer's confirmation → mass production" can be fully controlled. We can give immediate corrections and suggestions according to the preliminary designs and sketches provided by customers before mass production. We can effectively shorten the product development time, solve the problems, control the cost, and form a consensus on production quickly, so that our customers who emphasize on time to market can have more competitive advantage and seize the business opportunity successfully.

Metal Parts Processing Solutions

Precesion Parts and Full Services

We specialize in the field of brass parts for the bathroom hardware industry, various types of valve parts and auto parts, etc. We provide customers with complete and excellent metal parts processing solutions including mold design, fixture design, programming, 4-axis/5-axis simultaneous machining, 3D surfacing, rapid prototyping and surface treatment, etc. Over the years, we have succeeded in helping our customers to achieve a high level of overall consistency in the quality of their parts, shorten the production cycle, effectively reduce production costs, improve production efficiency, and enhance the competitiveness of our customers in the market.

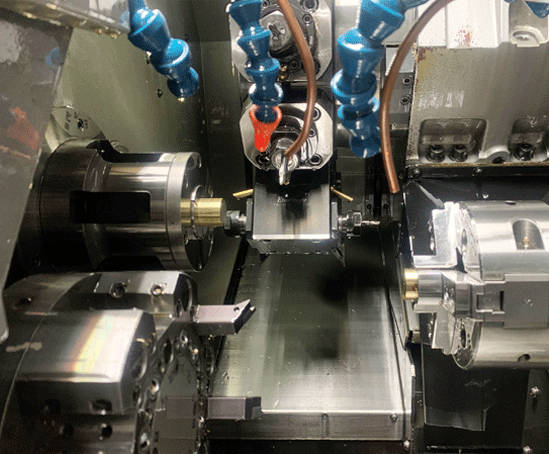

CNC Turning and Milling and Multi-tasking

In the market, there is a lot of demand for precision parts with complex tolerances and high precision, and Fong Shen is able to meet this demand with its CNC multi-axis, multi-processing complex high performance machining capability and solid technology. This machining and development capability can bring benefits to customers including lower cost, faster turnaround time, and superior quality precision parts...etc.

Multi-axis

The TAKAMAZ CNC lathe allows our engineers to complete the entire machining of a complex part with only one operator, which not only significantly increases the productivity, but also greatly reduces the potential for the workpiece to become damaged due to multiple operations and multiple processes.

Multi-processing

Our CNC lathe can perform many different operations, including turning, milling, boring, tapping, and drilling. Since the single machine performs simultaneous five-sided turning and milling with one check. The machining accuracy can be greatly improved, and the parts can also be completed in a shorter time with higher accuracy and repeatability.

CNC Milling Machine Production Line. Dynamic Four-axis Machining

The equipment of our CNC cutting center is equipped with the fourth axis, which can achieve four-axis simultaneous operation to meet various machining parts milling plane, surface, groove, spiral... etc., It also can manufacture multi-angle, 3D surface planing precision processing, and is capable of processing 2 to 10 parts at the same time to improve production efficiency.

Flexible Processing Production Capability

We have advanced vertical machining center production lines for various applications such as castings, die-castings, aluminum castings, extrusions, forgings... and other parts that can be machined with high speed and high precision. We have the capability to manufacture large-quantities parts and assembly components, but are still flexible to produce small-quantities parts and prototype work. We are focused on meeting our customers' needs, whether it is accuracy, reliability, on-time delivery or value.

FONG SHEN METAL MACHINING CO.,LTD

Phone:+886-4-7716669、+886-4-7719077

Fax : +886-4-7719348

信箱:fong.shen@msa.hinet.net

Address : No. 101-1, Liaocuo Ln., Lukang Township, Changhua County, 50565, Taiwan (R.O.C.)